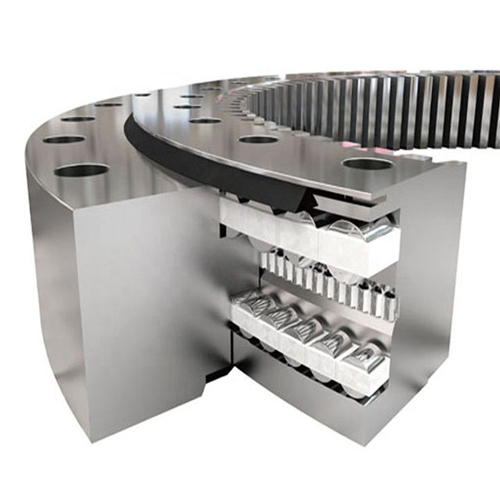

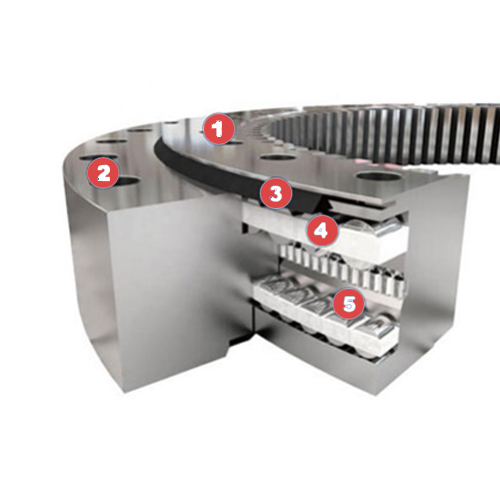

About product

The Marine Three-Row Roller Bearing, also known as a three-row cylindrical roller combination slewing ring bearing, is designed to handle high load capacities, making it ideal for applications with heavy loads. This type of slewing bearing consists of three seating rings, with separate upper, lower, and radial raceways. Each row of rollers can bear axial and radial loads independently, making it one of the highest load-carrying capacity options available.

- Ring material options: 42CrMo, 50Mn, or C45.

- Cage material options: Steel 20 or ZL102 cast aluminum alloy.

- Spacer material options: Nylon 6 or nylon 66.

- Quenching hardness of raceway: HRC55-62, ensuring durability and strength.