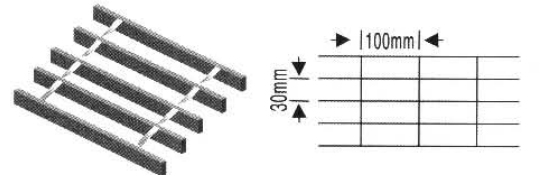

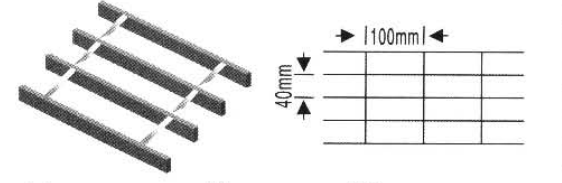

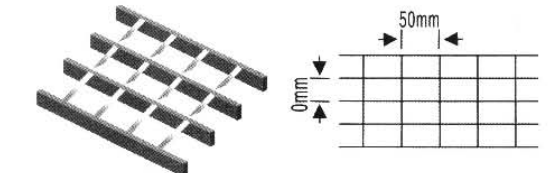

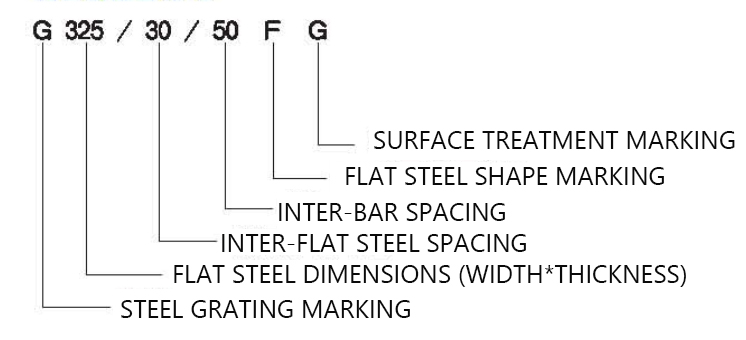

About product

Marine steel bar grating is indeed known for its high quality and is widely used in the shipbuilding industry. It offers durability and strength, making it suitable for various applications on ships. Some common uses of marine steel grating include catwalks on ships, machine furnace storehouses, deck walkways, warehouse platforms, and more.