About product

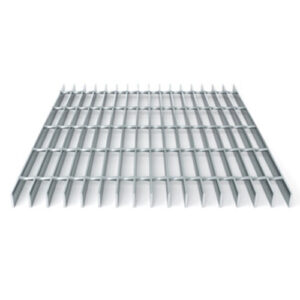

Marine Galvanized Steel Bar Grates find extensive use in channels, deck walkways, machine furnace storehouses of ships, warehouse platforms, chimneys platforms, bridge platforms, and other applications. It is specially designed to meet the stringent demands of the shipbuilding industry. To ensure its suitability, marine steel bar grating undergoes rigorous quality checks, including careful material selection, precise processing techniques, specialized welding processes, proper packaging of edge flat steel, adherence to twisting lever specifications, meticulous fixed plate welding, and achieving the required hot-dip galvanized zinc layer thickness.

- 25×5mm galvanized grating

- The 32×3mm galvanized steel grating

- 40×3mm galvanized bar grating

- The 50×5mm galvanized grating