About product

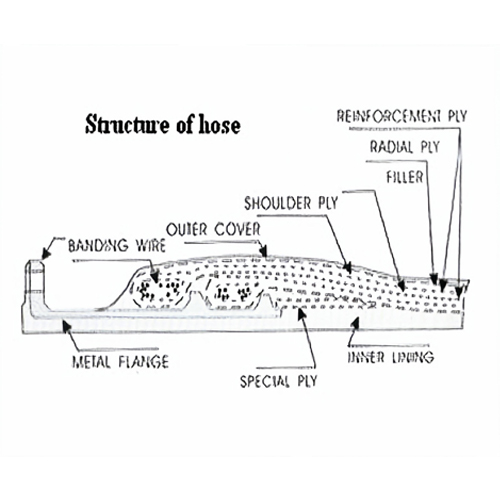

A marine rubber discharge hose is a tubular rubber product designed specifically for the transportation of water and sand. It consists of an inner and outer rubber cover, as well as a skeleton layer. The skeleton layer can be made from various materials such as cotton fiber, synthetic fiber, carbon fiber, asbestos, or steel wire. The inner and outer rubber layers can be composed of natural rubber, styrene-butadiene rubber, butadiene rubber, and other similar materials.

- Connects dredging equipment for efficient material removal.

- Handles abrasive materials with resistance to abrasion.

- Offers flexibility and maneuverability during dredging operations.

- Withstands high pressures and vacuum conditions.

- Incorporates buoyancy features to prevent entanglement.

- Available in various sizes and lengths to suit requirements.