About product

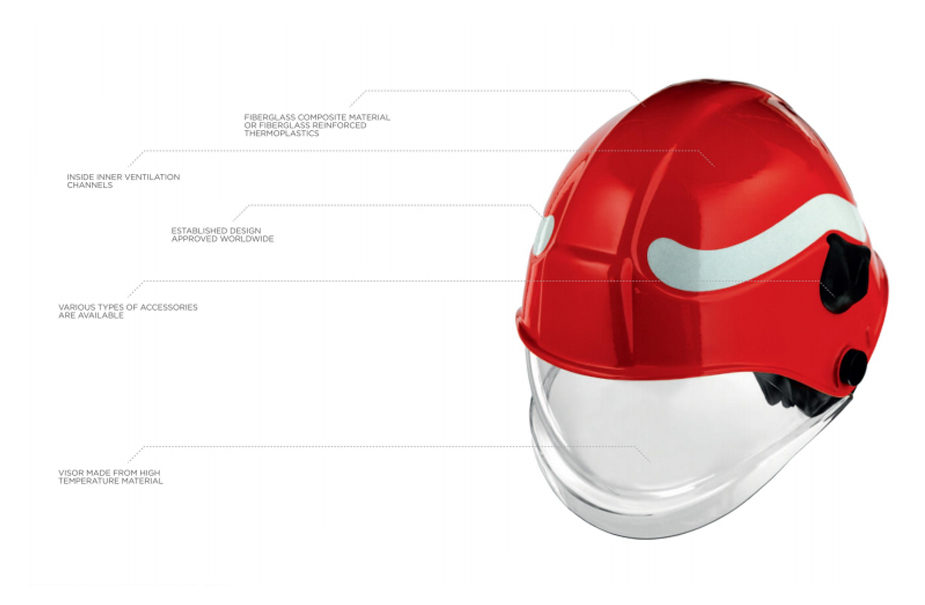

The marine firefighter helmet, or fire fighting helmet, or fire helmet, represents a pinnacle of professional-grade protective equipment specifically tailored for the rigorous demands of firefighting operations in marine environments. As a marine fire fighting equipment, meticulously engineered with advanced features and premium materials, this fire helmet prioritizes the safety, comfort, and effectiveness of firefighters on board ships.

- Lightweight Design

- Extreme Temperature Resistance

- Long-Term Heat Resistance

- Enhanced Impact Resistance

- European Standards Conformity