About product

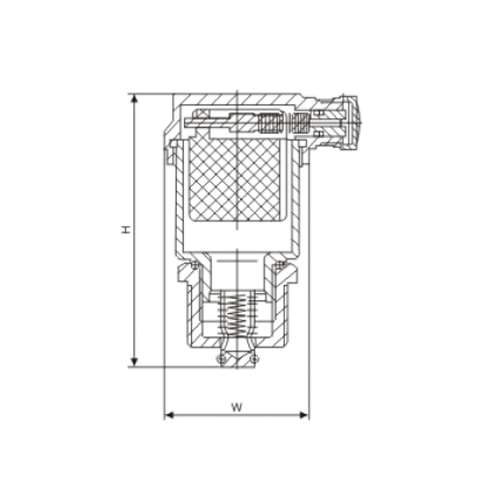

The Marine Brass Forging Automatic Exhaust Valve is designed specifically for marine applications. It is forged from brass, ensuring durability and corrosion resistance. The valve is suitable for use with a variety of working mediums, including cold and hot water, gas, and oil.

The valve can operate within a nominal pressure range (specific value not provided), making it suitable for different marine systems. It is designed to withstand a working temperature range starting from -20℃ and going up to a maximum temperature of 150℃.

With a thread criterion of 55° inch pipe thread and a thread standard that adheres to the same criterion, this valve is compatible with standard pipe fittings, facilitating easy installation.