About product

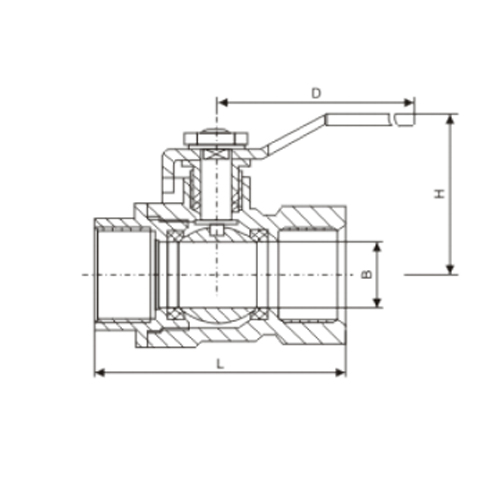

The Marine Threaded Brass Ball Valve Type 216 is a versatile valve designed for a range of applications involving the control of cold and hot water, gas, oil, and other compatible fluids. With a nominal pressure rating of PNs 1.6MPa, it is capable of handling various pressure conditions.

This ball valve is suitable for use in different temperature environments, with a working temperature range starting from -20℃ and going up to a maximum temperature as specified. Its construction with threaded connections adheres to the 55° inch pipe thread criterion, ensuring compatibility with standard pipe fittings.

The Marine Threaded Brass Ball Valve Type 216 combines reliable performance and ease of installation, making it a practical choice for fluid control in marine and other industrial applications.