About product

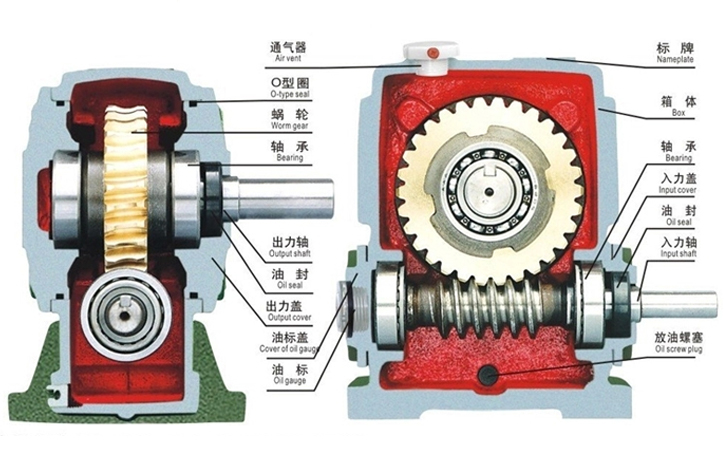

A worm gearbox is a type of winch gearbox. It consists of several essential components, including a worm gear, worm, shaft, bearings, housing, and various accessories. The gearbox can be divided into three main parts: the housing, worm gear, and shaft with bearings.

- Integrated Housing

- Housing Types

- Input Shaft Options

- Output Shaft Variations

- Shaft Orientation

- Multiple Reducers Combination