About product

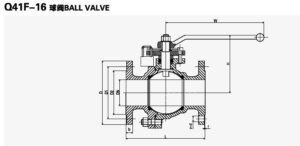

The Q41F Ball Valve is designed with a spherical closure featuring a circular passage that rotates around a vertical axis for precise opening and closing of the flow channel. With the valve stem’s rotation, the sphere moves accordingly, ensuring a tight seal.

This type of valve requires a mere 90-degree operation and minimal torque to achieve a secure closure. To cater to specific operational conditions, various driving mechanisms can be incorporated, resulting in diverse control methods such as electric ball valves, pneumatic ball valves, and hydraulic ball valves.

Explore our range of Q41F Ball Valves, Q641F Pneumatic Ball Valves, and Q941F Electric Ball Valves for exceptional flow control solutions tailored to your needs.