About product

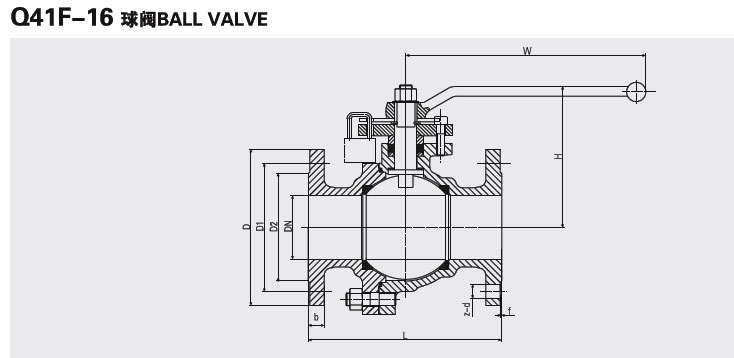

The working principle of carbon steel flanged ball valves relies on the rotation of the valve stem to open or close the valve. These ball valves are characterized by their lightweight design, compact size, ability to be manufactured in large diameters, excellent sealing performance, simple structure, and convenient maintenance. The sealing surface and ball surface remain in close contact when the valve is closed, reducing the risk of erosion by the medium

The main features of steel ball valves include their compact structure, ease of operation and maintenance, suitability for general working media such as water, solvents, acids, and gases, as well as their ability to withstand harsh working conditions with media such as oxygen, hydrogen peroxide, methane, and ethylene. The valve body of a ball valve can be either integral or modular. It is recommended to install this type of valve in a horizontal position within the pipeline.