About product

The Marine MD Series wafer butterfly valve is a type of valve used for controlling the flow of fluids in various applications. When comparing it to the YD series, there are a few notable differences:

- Flange Connection: The MD Series wafer butterfly valve has a specific flange connection, which means it is designed to be connected using a specific type of flange.

- Handle Material: The handle of the MD Series wafer butterfly valve is made of malleable iron.

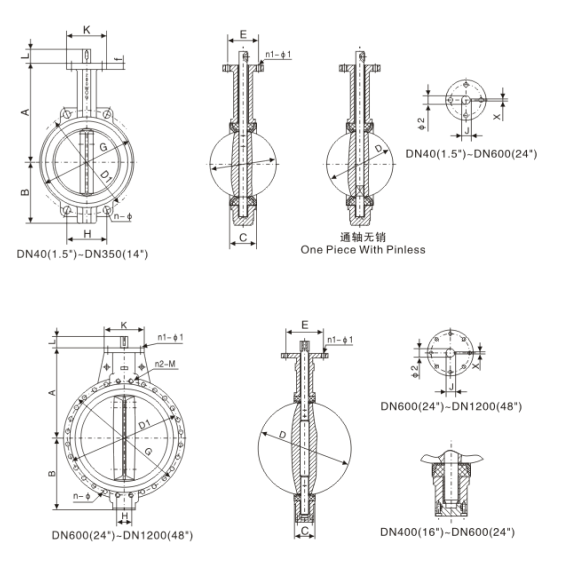

MD Wafer Butterfly Valve Drawing