About product

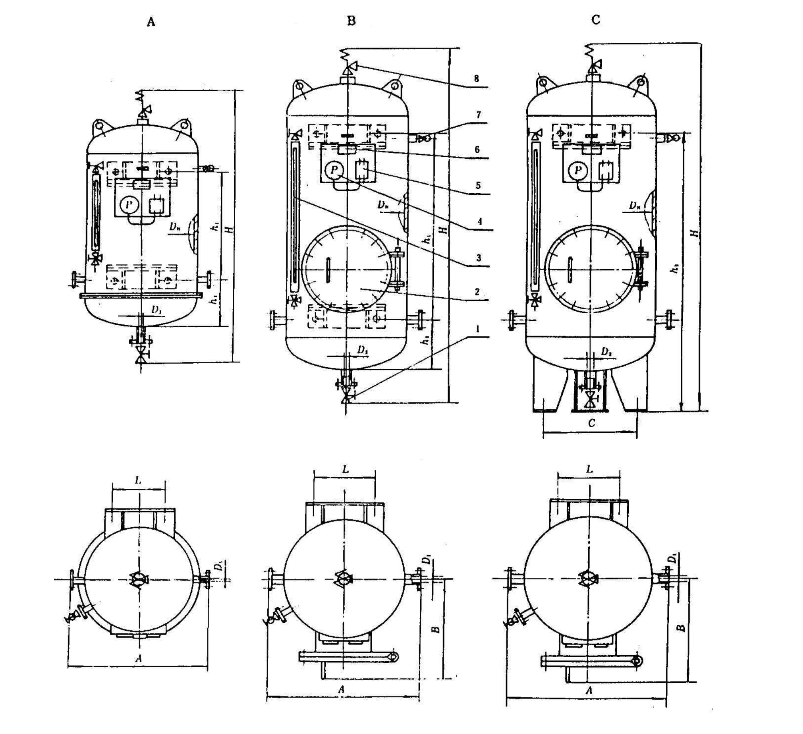

The YLG Series Pressure Water Tank is a water storage tank, designed to supply fresh water for living and cleaning purposes on ships and drilling platforms. This pressure tank operates on the principle of using pressurized water from a pump, typically provided by the shipyard. The pressurized water is used to compress the air inside the tank, creating a suitable air pressure within the tank. This ensures that the water inside the pressure tank is maintained at the desired pressure, allowing for the provision of fresh water to the crew members on board.

- Liquid Level Meter

- Pressure Gauge

- Pressure Controller