About product

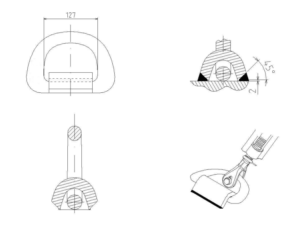

Our tie-down port is a sturdy and weldable anchoring component featuring a strap and D-ring, characterized by a substantial breaking load capacity of 36 tons (BL36t). It is purposefully engineered for seamless integration with a turnbuckle. This multifaceted lashing point exhibits adaptability for both in-plane (in-line) and out-of-plane loading configurations, accommodating diverse securing requirements.