About product

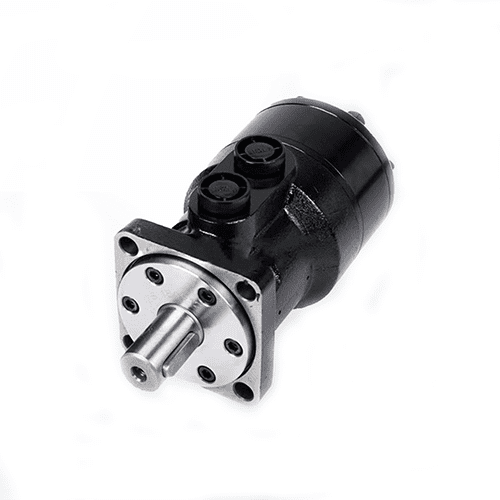

The Orbital Hydraulic Motor BMR 80 is a specific model of hydraulic motor that falls under the category of low speed, high torque hydraulic motors. As an orbital hydraulic motor, it operates based on an orbital principle, where an eccentric shaft causes an orbiting motion of the internal components.

Low speed high torque hydraulic motors like the BMR 80 are known for their durability and longevity. They are built to withstand harsh operating conditions, including high pressures, temperature variations, and contamination. This ensures reliable performance and minimizes downtime in industrial environments.

- The motor’s driver-linker design prolongs its operating life.

- The distribution system is specially designed to meet low noise requirements.