About product

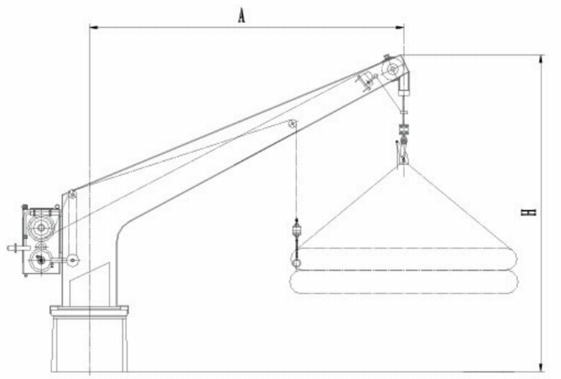

A Liferaft Handling Crane is a type of slewing crane specifically designed for the purpose of handling liferafts on ships or offshore installations. It is considered the simplest execution of slewing cranes available for liferaft operations.

These cranes are designed to meet the requirements set by the International Convention for the Safety of Life at Sea (SOLAS) regulations and are MED-certified. This means they comply with the safety standards and regulations mandated for liferaft launching appliances.