About product

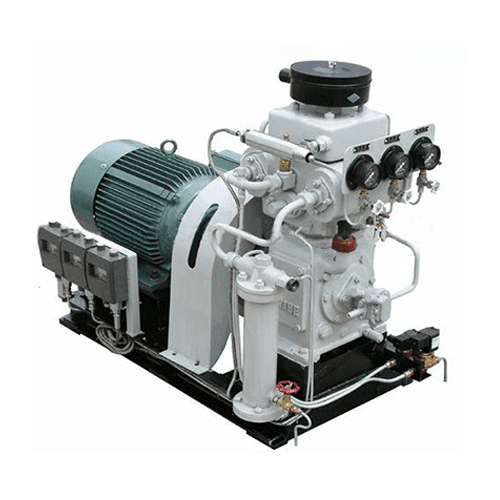

The WP Series Marine Air Compressor is a highly efficient and reliable compressor specifically designed for marine applications. It incorporates various advanced features to ensure optimal performance and durability in demanding marine environments.

One notable feature of the WP compressor is its air-cooled intercooler and aftercooler system. This design prevents overheating by efficiently dissipating heat from the compressed air, maintaining stable operating temperatures. Additionally, the compressor is equipped with a built-in moisture separator, effectively removing water and contaminants from the compressed air to ensure clean and dry output.