About product

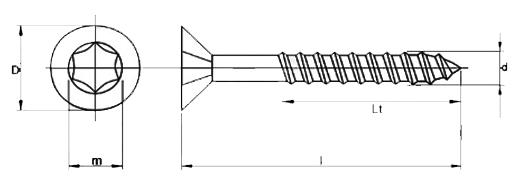

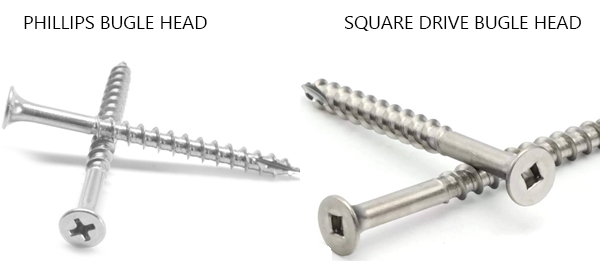

Marine stainless steel deck screws are the ideal choice for marine environments due to their exceptional corrosion resistance. These bolts feature a thin shank for easy penetration into wood and a self-countersinking head that creates a flush finish. With their square drive design (also known as Robertson drive), they eliminate the risk of cam-out, ensuring a secure and reliable connection. The length of these screws is measured from the top of the head to the tip, allowing for precise sizing and proper installation. Trust marine stainless steel deck bolts for lasting durability and performance in your marine decking projects.