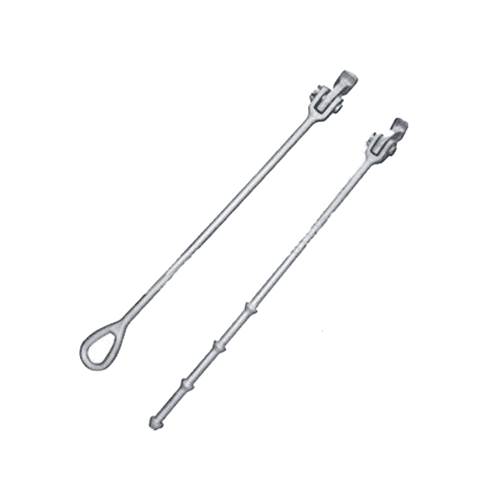

About product

The lashing high-tension rods are designed with the following specifications:

- They are constructed from high-tensile steel, ensuring exceptional strength and durability.

- These rods are engineered to withstand high levels of tension, with a minimum breaking load of 500 KN (kilonewtons). This robust design ensures reliable performance and safety, even when subjected to heavy loads and forces.

- The lashing high-tension rods can be manufactured to meet specific dimensional requirements upon request. This allows for flexibility, accommodating various applications and installation needs.